Connecting and Analyzing Data from Measurement Instruments

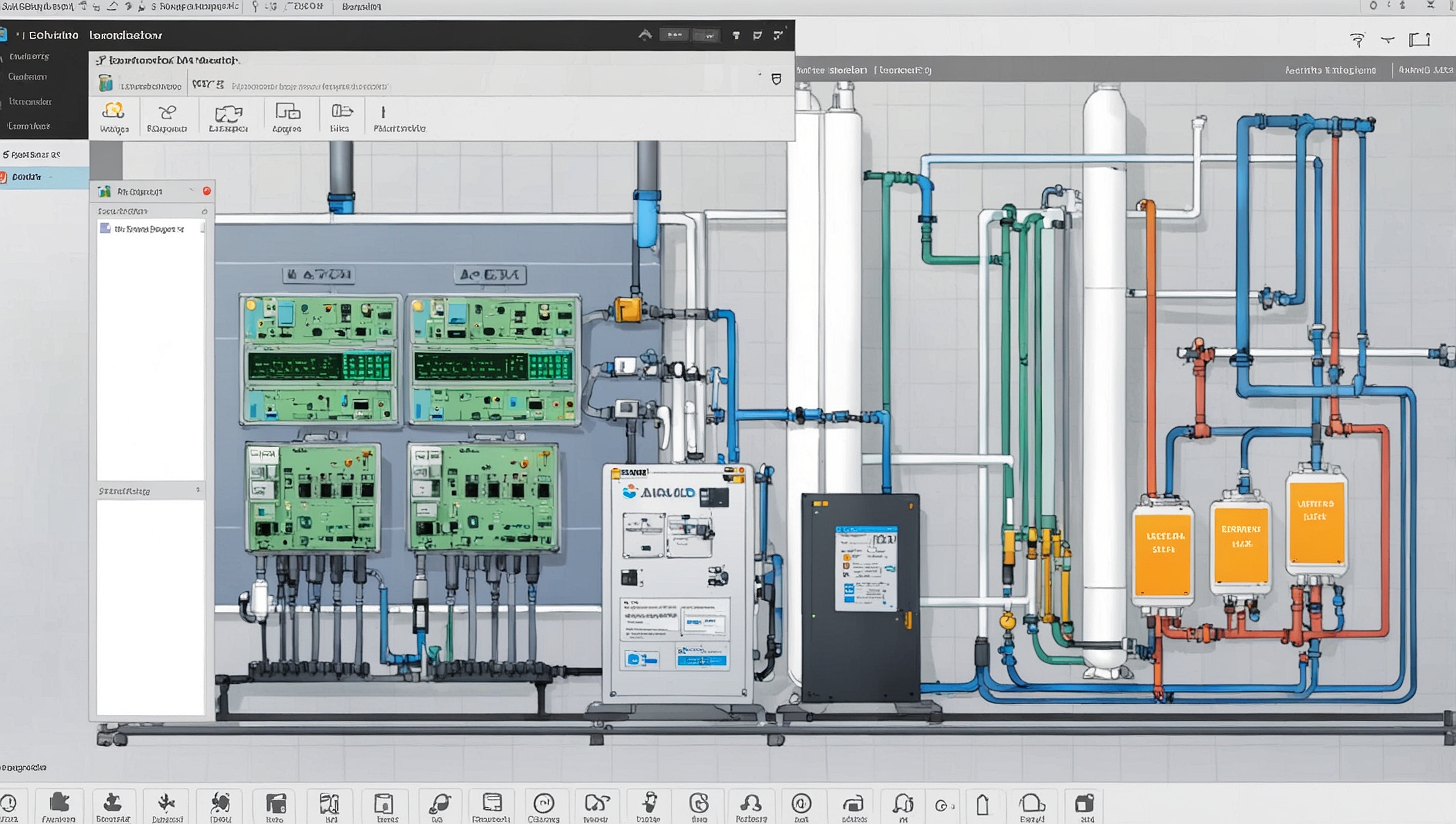

This project focuses on developing software that can connect to various measurement instruments to read and process data according to the client's requirements. The software will facilitate rapid and accurate calculation of various formulas, such as Offset and Calibration values, and provide detailed and easily understandable analytical reports. The software will also be developed as a Web Application to enhance usability.