Service Solution

About Project : Production Line Monitoring

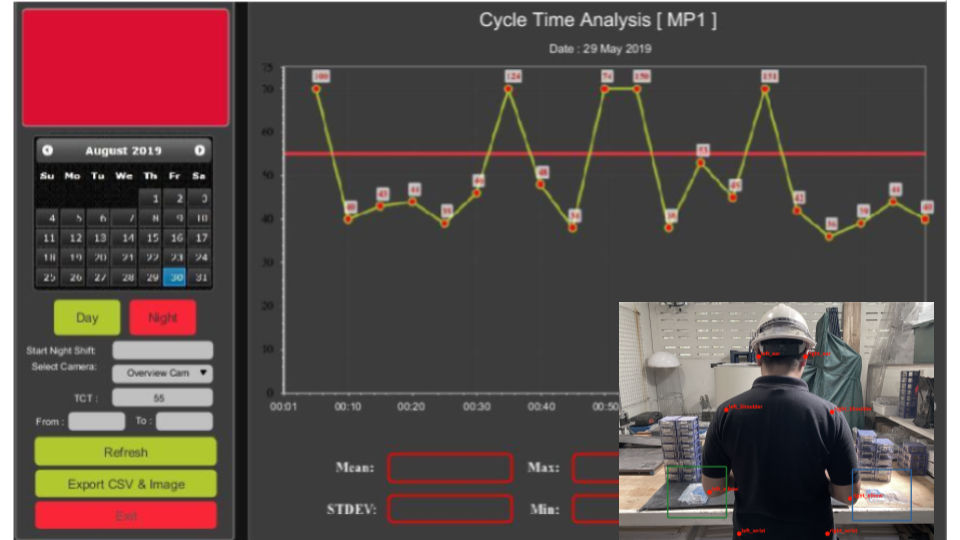

This project is a significant step towards helping the factory reduce production losses significantly and increase the efficiency of the production process. The project focuses on reducing production losses by monitoring and analyzing the production efficiency in the production line using PLC, sensors, IP cameras, and gateways. This helps in identifying and promptly addressing production issues, reducing work time, optimizing complex production processes, and enhancing the efficiency of operators in the production process. Data displayed through dashboards, graphs, and Excel reports provide a clear overview of the production process. The benefits include reducing production chaos and improving factory production efficiency effectively.

Scope of Work

- Device Connectivity: Develop software that supports connectivity with various devices through multiple protocols such as PLC, sensors, IP cameras, and gateways to track and analyze production efficiency.

- Issue Identification and Improvement System: Develop a program that can identify and address production issues promptly, allowing for customizable settings, alerts, and the ability to review past video clips.

- Web Application Development: Design and develop a user-friendly web application that is accessible across all platforms through web browsers. This application should include data storage and management features to enable easy access and editing of information through the web interface.

- Data Analysis and Reporting: Create modules for data analysis, including statistical values and trend analysis, and establish a reporting system in various formats such as PDF and Excel for easy understanding. Develop dashboards to display real-time data efficiently

Project Achievements

This project focuses on developing a comprehensive production management system aimed at significantly reducing production losses and enhancing overall factory efficiency. The system is designed to swiftly identify and address issues in complex production processes through a user-friendly web application, facilitating efficient data management and accessibility. It incorporates advanced data analysis modules and generates easily comprehensible reports, providing executives with a clear overview of production processes. Additionally, the system features robust data backup and storage functions, ensuring data security. By integrating these elements, the project aims to elevate factory operations, boost competitive advantage, and drive sustainable development in the manufacturing industry. This holistic approach to production management empowers decision-makers with real-time insights, enabling proactive problem-solving and continuous improvement in the production ecosystem.